Flexible Operating Software for higher User-Friendliness

ILLIG GROUP

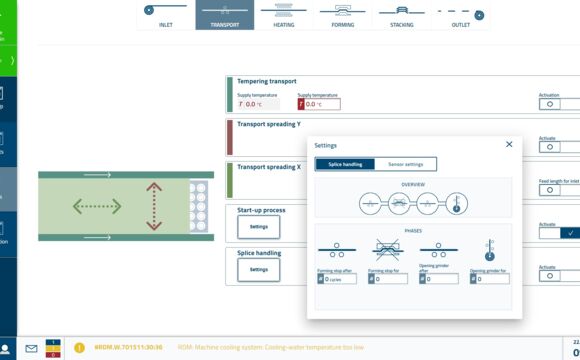

When it comes to improving industrial productivity, efficiency and safety, machine visualizations have an important role to play. Attractively designed and intuitive user interfaces are increasingly replacing purely technical developments.

Illig Maschinenbau GmbH & Co. KG, the global leading manufacturer of thermoforming and packaging systems, rose to this challenge and began to fundamentally readdress the visualization concept of its machines.

Illig kicked off this technically challenging project at the start of 2022. But their experts had already put a lot of thought into restructuring the numerous functions and operating modes of their machines. One major goal was to increase system user-friendliness with smooth human-machine interaction. Another important concern was to simplify the internal visualization configuration for the machines' various technical features and options. Another requirement was for easier integration of existing plants into the customer value chain.

Open visualization software

Illig started an extensive evaluation process in search of the ideal software. The product had to be scalable and flexible – to be able to react quickly to future requirements. Their experts paid particular attention to a web-based implementation, expandability, openness to third-party systems, and the scope of included functions. "We evaluated several solutions. In the end, Bachmann's OPC UA-based web visualization solution atvise®, with its open system architecture, was what convinced us," says Dr. Andreas Moser, Head of Software Development at Illig.

Flexible construction kit

atvise® open interfaces also enable the simple integration of various UI frameworks; a crucial point in this case. "By including React as a framework, we were able to decouple the machine logic from the software's business logic, meaning that high-level language developers can also be involved in programming the visualization," explains Dr. Moser. The advantage: Programmers do not need to know anything about the machines, or the controllers, and the usual training was not necessary.

Finally, configuration files for the various technical features of the machines are simply transferred to atvise® software

via an import/export function, or read from there. Linking components and the connection to the control system takes place in atvise®. "When the machines are delivered, the only visualizations on display are those that are relevant for each respective machine," says the development manager.

Uniform operating concept

During the development of new operating software ILLIG EasyTOUCH, emphasis was placed on simplifying the operation of every Illig machine. The user interface now reflects the different applications required by operating personnel. Thus, there are different menus for production employees, machine equipment operators, or maintenance personnel. Users are shown individually relevant information as soon as they log in. The necessary authorizations and role definitions were implemented using atvise® standard functions, and they can be easily extended and adapted by the customer. The atvise® OPC UA interface also allows individual customer needs to be quickly addressed. Third-party systems and machines can therefore be quickly integrated into Illig's operating concept.

Ambitious schedule

The project schedule was very ambitious. There were just four months between the kickoff at the beginning of 2022 and the presentation of the first functioning prototype. In the meantime, every component for the construction kit is available. "With our software concept, different developers can work on several levels simultaneously. Each team member can concentrate on his or her individual field. This enabled us to keep to the schedule," says Dr. Moser. "Support from Bachmann experts during the atvise® programming, and their quick response to questionsand necessary extensions, was also very helpful."

Illig is now working at full speed on visualizing the internal machine configuration in atvise® for up to 60 options per machine family. All Illig machines are to be delivered with the new ILLIG EasyTOUCH operating software and hardware as early as 2024. In the future, operating personnel will be able to operate any and every Illig machine without additional training.

Photo credit: © Illig Group

Customer Profile

Customer: ILLIG Group

Industry: Mechanical engineering

Project: operating software and hardware ILLIG EasyTOUCH

Product: atvise® hmi

PLC(S): Multiple