Extrusion goes digital

Exelliq optimizes processes with atvise®

Digitalization has also impacted the profile extrusion sector. Machine manufacturer Exelliq is one of the first providers of digital solutions for extrusion lines. Exelliq was able to optimize its processes with support from atvise®, software for visualization and control room solutions based on pure web technology and OPC UA provided by Bachmann Visutec, and with support from the distributor, Industrial Automation.

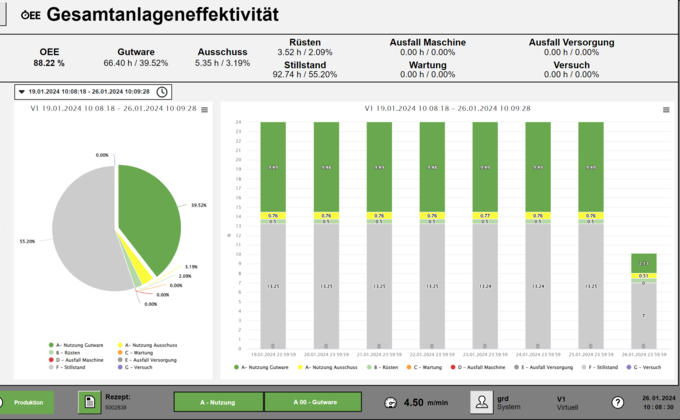

In 2018, the software developers at Exelliq already started thinking about the digitalization of their extrusion systems. The objective was to achieve a stable production process and significantly increase production reliability. The result was the DIGI.LINE digital production line. With DIGI.LINE the extrusion process can be digitally controlled and optimized in real time. Moreover, material consumption is minimized and output is increased. Exelliq's calculations show yearly savings in the production of window profiles of up to €127,000 compared to analog lines.

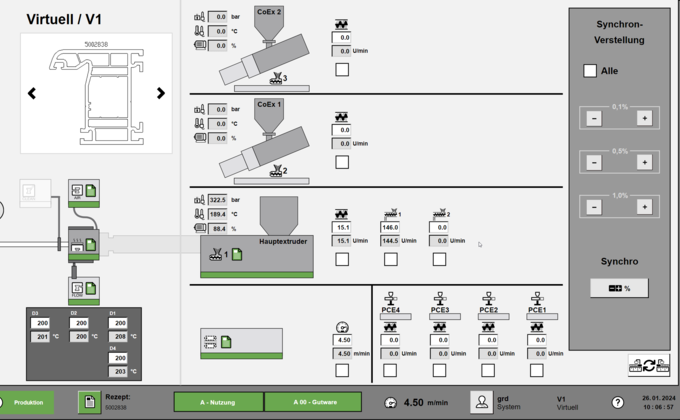

The heart of the DIGI.LINE is the DIGI.MASTER; and atvise® is the heart of the DIGI.MASTER. This is where all information of the sub-areas comes together, DIGI.CONTROL (PLC with control loops), FLOW.MATIC (control of the full profile sections), DIGI.TANK (profile shape), PROFILE.RAISER (safe raising of the profiles), DIGI.PUL (caterpillar puller or belt puller), DIGI.CUT (profile cutting), and DIGI.SCALE (profile weighing).

A decision for openness and flexibility

To implement Exelliq's roadmap, SCADA systems from the leading providers were subjected to extensive testing. Ultimately, the decision-makers selected atvise®. It fit perfectly into the development team's philosophy. It was a SCADA solution based on OPC UA. Therefore, connections to the line's many peripheral systems and controllers could be implemented quickly and without complication. Thus, the requirements of the first part were met. With atvise®, for the first time it was possible to establish comprehensive data recording.

In this regard, the two lead software developers at Exelliq, Daniel Grill and Christoph Huber, commented, "For the first time, we succeeded in seamlessly recording and visualizing the process data. And what's more, with the integrated web server, customers were able to access this data from anywhere in the world." A technological advancement that quickly proved successful. Many digitalized lines have already been delivered around the world.

End-to-end data transparency

The prerequisite for the DIGI.LINE digital extrusion line is the complete overview from the extruder to the end-of-line weighing table. This data transparency ensures that all information can be visualized, further processed, and that the system parts can be controlled. All this data is brought together in the DIGI.MASTER, i.e. in atvise®. The data either comes directly from the controller, via OPC UA – TCP/IP or via so-called LINE.SERVERS (edge devices on Linux) that are equipped with an OPC server. The edge devices read out the machine data and relay it to atvise®. For older machines, such as old extruders, Grill and Huber wrote the drivers themselves. This means that even lines provided by third-party manufacturers can be implemented into the overall system. To do this, on the customer side, the controllers of analog equipment must be adapted to obtain data.

What Exelliq has experienced is the fact that when these tasks are concluded, the customers and owners quickly learn to appreciate the advantages offered by digitalization. Previously, in the extrusion sector in particular, reliable information was quite rare. Everything was based on empirical values and analog displays. Thanks to the changeover, now there is live information concerning temperature curves, pressure curves, as well as other data.

Integrated web servers save time

One major advantage offered by atvise® is its web capability, as Grill explains citing an example: "One day a production supervisor was at home and checked his web-enabled end device. He realized that there were process deviations in a non-staffed production facility. He logged into the system with a secure VPN connection, verified the deviating parameters and corrected them accordingly." However, even if the facility is staffed, the atvise® web servers offer machine operators a seamless monitoring capability. Accesses are regulated by a hierarchical rights system to prevent misuse or errors.

With atvise® development time is reduced

Many available standard functions, such as a multilingual user interface (German, English, French, Polish), a smart web server, data analysis with aggregation, and the sophisticated object concept, save Exelliq experts a lot of development work. The ability to create graphics is another significant advantage. Graphics are created once as SVGs (Scalable Vector Graphics) and then stored as objects. This means that they can be used over and over again; they just need to be re-parameterized. Likewise, the open analysis libraries and trends provided in atvise® were adapted to meet the needs at Exelliq. Here as well, data analysis merely needed to be parameterized and its appearance slightly adjusted.

Flexible openness

Reliable data analysis is essential to monitor and control extrusion systems. In this regard, atvise® offers an extensive portfolio, which however gives the owner virtually unlimited design freedom. Daniel Grill: "As soon as the framework hits its limits, in spite of the great support, specific extensions can be implemented with the script engine. This openness offers us virtually unlimited possibilities and we can implement custom solutions without major cost outlays. This is a significant advantage over heterogeneous SCADA systems," states Grill. "In this regard we were always supported perfectly without any bureaucracy by Industrial Automation and Bachmann Visutec." Even for functions that were not yet implemented in atvise®. For example, the recurring requirement of a current time stamp for older, perfectly-functioning systems that do not conform to current standards. Bachmann Visutec evaluated the requirement, which is also a significant requirement in other industries, incorporated it into their roadmap, and implemented it in the next release.

Another tool for integrating third-party products is the OPC UA Line. This is a standardized interface developed by Exelliq for profile extrusion. It ensures uniform structures, standard naming conventions for variables, and clear definition of the underlying units. The OPC UA Line is the connecting link between the extrusion lines and atvise®. To ensure that the flood of data points need not be manually worked through point-by-point, with the support of Industrial Automation, the two specialists wrote scripts in atvise® that automatically create more than 4,000 data points. In parallel, the entire data configuration and data recording are ensured. Consequently, export/import lists are eliminated, and this in turn saves significant time when implementing lines. A new line can be commissioned quickly with just a few mouse clicks.

Exelliq is also impressed by the stability of atvise®. The architecture enables a customer's new line to be configured and commissioned as a background process in running operation without interruption. Nevertheless the web server works through the other lines flawlessly. There is no need to stop the system. This capability offers the owner incredible savings.

With atvise® into the future

First and foremost, Daniel Grill sees the future of the DIGI.MASTER in the increased quality of the DIGI.LINE. For example, the lines will be better monitored for scrap recognition, scrap detection, and surface defects but also the networking within the lines will be brought to an even higher level. Likewise, customer requirements will be given greater consideration. In this area, Grill sees significant potential, since the industry is only in the initial phases of digitalization.

Conclusions

With atvise®, Exelliq has established a major competitive advantage: It was the first company to offer digitalization in this market. This was possible because Exelliq was able to save hundreds of development hours, thanks to the standard features provided by atvise®. Consequently, the Exelliq developer team benefits from the Eisenstadt software architects and can consistently generate customer solutions that make profile extrusion operation more efficient and more profitable.

Customer profile

Distributor: Industrial Automation GmbH

Customer: Exelliq Austria GmbH

Industry: Machine/Plant building

Project(s): SCADA for profile extrusion

Product: atvise® scada

PLC: multiple

About the author: Helmut Zauner is an independent industry journalist and owner of the PR agency HZ.Comm and wrote this article for 'Austromatisierung' magazine on behalf of lndustrial Automation.

www.hzcomm.com